Construction Technical Innovation Is the New Frontier

Construction is finally changing with an era of construction technical innovation. All over the world, unions are growing weary of the elephant in the room – automation. “Is this robot going to steal my job?” is the question on crew members’ minds as new technologies are rolled out by the day.

Over the last 20 years, change in the construction industry has been slow while technological capabilities have reached new horizons. The problems in construction are numerous, but among the largest is that the industry has been lagging in productivity growth. Innovation is high-risk and capital-intensive, which has caused companies to stick to traditional methods. Although there are lower barriers to entry, resistance to change has long plagued the industry.

The Covid-19 pandemic has forced companies to rethink their strategies. Challenging conditions and new influxes of investment are expected to accelerate change in construction. Evolving industry standards and customer expectations will favor companies that are agile with technology and the benefits that come with it. In the post-Covid world, companies that are fast to innovate will reign. Does this mean a multitude of jobs will become obsolete? To answer this, let’s find what role tech plays in construction today by studying examples and examine some other factors that will influence the future of construction.

Construction Technical Innovation to Foster Collaboration

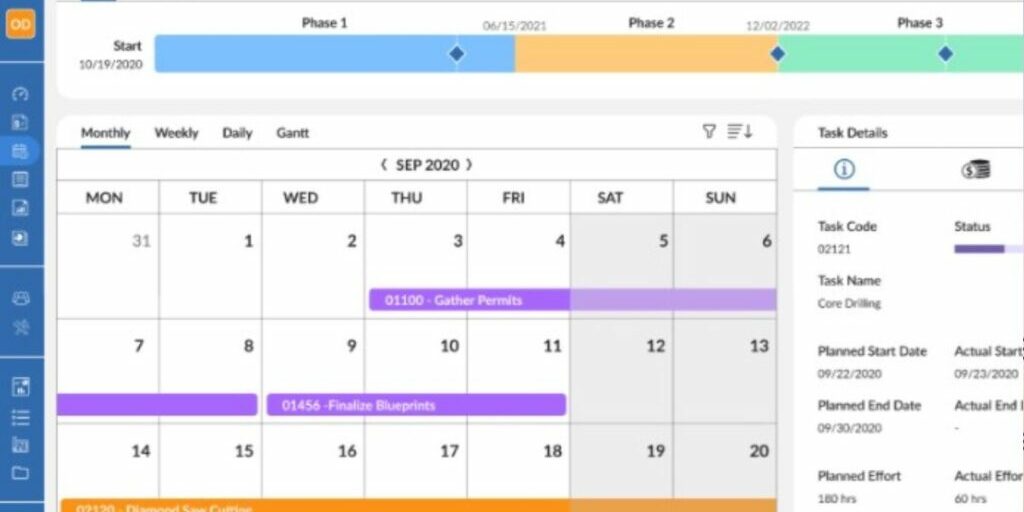

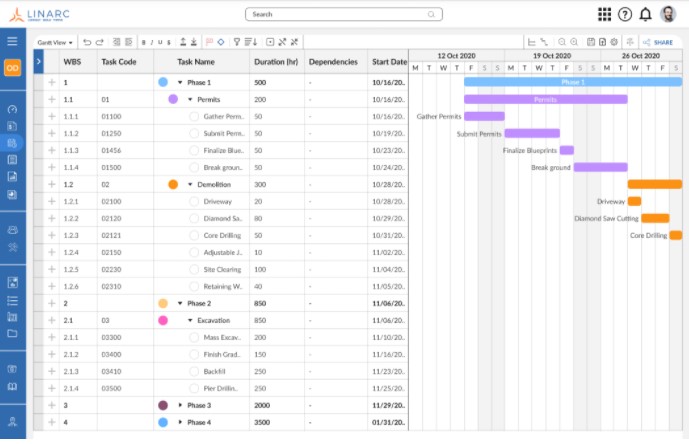

The construction industry is arguably one of the most collaborative environments in the world. Take a look around you and think of everything that has gone into transforming the land beneath your feet into the fancy office or cozy home that you enjoy today. From design and planning to foundations and interior design, many elements need to come together to complete the project. This can only be accomplished through a collaboration of different human resources. Though communications technology and high-speed internet have made it easier for teams to collaborate remotely, little research has gone into improving its effectiveness. The platforms currently used by construction firms are grossly unintuitive and cumbersome to use. Moreover, with companies using a host of different programs to carry out tasks, integrating them becomes an issue.

To counter these problems, Linarc is building an extensive collaboration suite tailor-made for the construction industry. Our mission is to serve as a comprehensive resource for construction teams. Linarc’s products connect a company’s stakeholders and internal teams to the entire value chain through cloud-based mobile and desktop applications. Innovative employee management, general contractor and subcontractor collaboration, sleek integrated schedulers, powerful dashboards, and performance reports are just some of Linarc’s exclusive specs. Our UI is streamlined to increase employee productivity while privacy is maintained across corporate strata and companies. At Linarc, we are pushing the boundaries of collaboration, and our efforts are geared towards transforming collaboration in the construction space for years to come.

Fundamental Changes

Modular construction is the most significant transition construction has ever witnessed, and it stands to revolutionize how buildings are built. Off-site manufacturing strategies and automated on-site assembly aim to industrialize construction by repetitive manufacturing of standard elements and assembling them in modules. This can help with increasing automation in the field and attract talented personnel in manufacturing. With the current scarcity of skilled labor and customers expecting accurate estimations of costs, modular construction is expected to be increasingly leveraged. A Global Market Insights report notes that Modular & Prefabricated Construction Market size was over USD 129 billion in 2019 and will grow at a CAGR of 7.1% from 2020 to 2026.

ConXtech is a chassis-based modular steel building company based in Pleasanton, CA. Factory-built assemblies significantly accelerate delivery, and patented interlocking mechanisms eliminate the need for on-site welding. This simplifies the entire design to delivery process and helps estimate costs accurately. Their end-to-end services are green, safe, and minimize wastage.

The advent of 3D printing is causing another fundamental shift in how construction will happen in the future. In 2004, Professor Behrokh Khoshnevis of the University of South Carolina attempted the first 3D printed wall using a technique called Contour Crafting. It was a great success and marked the beginning of 3D printing in construction. Contour Crafting uses a computer-controlled crane or gantry to build edifices rapidly and efficiently with substantially less manual labor. 3D printing concrete structures is faster, safer, and greener than traditional methods. The technology is still in its infancy because of slow adoption, but big names in the industry have partnered with startups to accomplish innovative projects. The concrete 3D printing market is expected to reach a market cap of $56.4 million by 2021.

Mobbot’s 3D printer includes an industrial robot with a print head that combines sprayed concrete with new technologies to obtain a smooth surface in a single manufacturing step. The patented technology is based on using cutting-edge robotic automation equipment to manufacture a reinforced 3-dimensional concrete structure. The method combines the freedom of 3D printing with the longevity of sprayed concrete.

Auxiliary Changes

Speaking of robots, our fascinating friends have successfully gone on to automate processes across industries, saving costs and even saving lives by conducting complex surgeries. Thankfully, robotics is finally seeping into the construction industry, with startups driving change. Barcelona-based Scaled Robotics aims to minimize rework in construction projects by using robots to carry out automated construction verification and automated progress monitoring. Through scanning techniques, they can provide crucial information to help localize mistakes and prevent costly errors. Their site monitoring robot can track the progress of the project and provide actionable information to site managers.

Similar to bots, drones have single-handedly changed how surveying is carried out. AI-powered software is capable of producing detailed maps of construction sites by processing the visual data captured by the drone’s camera. Drones are the quickest, safest, and most accurate solution to acquiring a variety of on-site information, for example, measuring stockpiles. This information can be shared with internal teams and clients. Drones are incredibly powerful as their ability to relay real-time information is coupled with resilience to external conditions and obstacles.

Chris Anderson, CEO of 3DR, a drone manufacturing company, had this to say about drones in construction: “On-screen, in the architect’s CAD file, everything looks perfect. But on-site, in the mud and dust, things are different. And the difference between concept and reality is where about $3 trillion of that $8 trillion gets lost, in a cascade of change orders, rework, and schedule slips. Drones are meant to close that gap.”

FalconViz is a Saudi Arabian startup that uses drones for 3D surveying and mapping. Their services include surveillance, inspection & monitoring, UHD images, HD videos, and 3D modeling. Their main concern in construction is to minimize the errors in the estimation of the budget. They can create models with .5 cm error margins and capture entire stockpiles, so that monthly reports for restocking can be accurately curated. Client testimonials reveal that the returns offered by the company are so valuable that their monthly rates are considered inexpensive.

The application of new technology to solve real-world problems is always fascinating. Augmented Reality (AR) is an interactive experience of a real-world environment, where objects in the environment are enhanced by information, often through visual or auditory means. Virtual Reality (VR) is a simulated environment that can be similar or completely different from the real world. Industry players are increasingly finding new use cases for AR & VR in construction that drastically improves accuracy, efficiency, and safety. Although adoption is slow and on-field difficulties are encountered, their potential for success is promising.

Suffolk Construction has partnered with New York’s VR startup InsiteVR to help its engineering teams meet virtually to coordinate, plan and resolve issues on a $100 million high school construction project in Florida. The team can participate in meetings with the help of a VR headset, and view plans, designs, and structures, all inside a virtual environment. The company has found the experience very rewarding, identifying unique issues which would have been challenging to diagnose using traditional communication.

Conclusion for Construction Technical Innovation’s Impact

The construction industry is fast becoming an exciting startup space. New entrants, backed by venture capital firms and private equity, are bringing disruptive technology into the industry. In a survey conducted by McKinsey at the height of the Covid-19 pandemic, a large number of key respondents believed that disruptive technology will begin the transformation of the construction industry within the next five years. With such high claims and expectations from technology, it is natural to assume that jobs will be entirely replaced by the arrival of super-intelligent, sentient robots. From reading the examples cited in this article, it should be clear that this is far from reality. In truth, although automation can accomplish amazing feats, it is still in its developing stages in construction.

Automation will serve as a friend to crew members in the near future, slowly changing the way things happen. In 20 years, the industry is expected to look very different, but future transformations will be supported by the arrival of a young, tech-savvy workforce.

What construction technical innovations are you looking forward to? Check out Linarc Construction Project Manager here.